All opportunities

Search...

Offers : 114

(filled) Development of a ZnO nanowire piezoelectric microsensor for measuring wall friction in hydrodynamic flows

Start date : 01/10/2025

offer n° CROMA-CMNE-05-14-2025

Doctoral thesis 2025-2028 at CROMA and LEGI

Development of a ZnO nanowire piezoelectric microsensor

for measuring wall friction in hydrodynamic flows

Detailed subject :

In the field of fluid mechanics, hydro and aerodynamicists are looking for disruptive sensor technologies that can be used to measure aerodynamic or hydrodynamic flows. The complexity of the Navier-Stokes equations means that experiments and simulations need to complement each other. Understanding flows in order to predict their behaviour and control them is a major challenge in this field. More specifically, one of the two important quantities in the fluid mechanics equations is wall friction (tangential force at the surface of an object during fluid/object interaction), the other being wall pressure [1]

The multidisciplinary consortium involved in this thesis brings together CROMA (C. Ghouila-Houri, G. Ardila), LEGI (S. Hoerner, P-L. Delafin), LMGP (V. Consonni) and G2ELab (L. Gimeno), to develop a new technology for wall friction microsensors, using nanomaterials (ZnO nanowires) and enabling measurements in liquid media (hydrodynamic flows).

Application context:

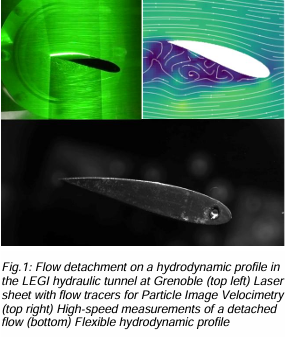

Blade flow control is an important issue in turbomachinery and aeronautics. In this project, we are focusing on a systematic problem associated with vertical-axis hydrokinetic turbines, where controlling the flow would not only improve performance but also extend their service life [2 – 4]. More specifically, the hydrodynamic phenomenon to be controlled is the detachment of the boundary layer on turbine blades: the flow no longer follows the geometry of the blade profile but separates from it, with the appearance of a recirculation zone (in the form of a vortex) directly above the blade surface. Controlling the flow over an airfoil – for example by actively modifying its geometry (morphing) – can prevent stalling and thus improve the performance of a turbine (See Fig. 1). In order to have an automatic closed-loop control mechanism, it is necessary to detect the separation of the boundary layer and its evolution along the surface of the airfoil. To this end, this thesis aims to develop a very thin sensor (so as not to disturb the flow around the profile). This sensor must be able to detect the level of wall friction and in particular the sign (positive or negative) and therefore the direction of this friction, in order to identify the point of detachment

Blade flow control is an important issue in turbomachinery and aeronautics. In this project, we are focusing on a systematic problem associated with vertical-axis hydrokinetic turbines, where controlling the flow would not only improve performance but also extend their service life [2 – 4]. More specifically, the hydrodynamic phenomenon to be controlled is the detachment of the boundary layer on turbine blades: the flow no longer follows the geometry of the blade profile but separates from it, with the appearance of a recirculation zone (in the form of a vortex) directly above the blade surface. Controlling the flow over an airfoil – for example by actively modifying its geometry (morphing) – can prevent stalling and thus improve the performance of a turbine (See Fig. 1). In order to have an automatic closed-loop control mechanism, it is necessary to detect the separation of the boundary layer and its evolution along the surface of the airfoil. To this end, this thesis aims to develop a very thin sensor (so as not to disturb the flow around the profile). This sensor must be able to detect the level of wall friction and in particular the sign (positive or negative) and therefore the direction of this friction, in order to identify the point of detachment

Technological context :

There is growing interest in piezoelectric devices as sensors using the direct piezoelectric effect. However, the best performances are obtained with materials whose toxicity level makes them either complicated to manage or forbidden to use for concrete applications (for example PZT containing lead). The work carried out at CROMA in a collaborative research context with LMGP aims to study piezoelectric nanocomposites using vertical semiconductor nanowires in order to obtain, through nanostructuring, high piezoelectric performance coupled with greater flexibility and less severe manufacturing conditions (low-temperature growth) [5- 7]. The interest in these developments lies, among other things, in the ability to exploit these materials to create new sensor concepts.

There is growing interest in piezoelectric devices as sensors using the direct piezoelectric effect. However, the best performances are obtained with materials whose toxicity level makes them either complicated to manage or forbidden to use for concrete applications (for example PZT containing lead). The work carried out at CROMA in a collaborative research context with LMGP aims to study piezoelectric nanocomposites using vertical semiconductor nanowires in order to obtain, through nanostructuring, high piezoelectric performance coupled with greater flexibility and less severe manufacturing conditions (low-temperature growth) [5- 7]. The interest in these developments lies, among other things, in the ability to exploit these materials to create new sensor concepts.

Nanowires generally have a diameter of several tens of nanometers and a length of around one micrometer (see Fig. 2). Thanks to this geometry, they generally have excellent crystalline quality and benefit from remarkable physical properties linked to their high surface-to-volume ratio. Zinc oxide (ZnO), which is semiconducting, biocompatible and composed of abundant elements, has many advantages and can be manufactured in nanowire form using a large number of deposition techniques. Thanks to its wurtzite crystal structure, ZnO nanowires grow along the piezoelectric c-axis. Vertically aligned arrays of ZnO nanowires are therefore sensitive to mechanical stresses and could be incorporated into piezoelectric nanocomposites to detect and quantify parietal friction in fluid mechanics.

Aim of the thesis :

The aim of this PhD thesis is to design, manufacture and characterise a miniaturised piezoelectric sensor based on ZnO nanowires for direct measurement of wall friction, in a hydrodynamic flow and on a scale model.

To achieve this objective, the student will participate in : I) conception and design using multiphysics simulations based on the know-how in the consortium of laboratories (CROMA) [ 8- 9], II) development of processes for the manufacturing and integration of ZnO nanowires via the various cleanroom and material growth platforms in Grenoble (CROMA, LMGP, CIME, PTA) [ 6], III) electrical, electromechanical and possibly AFM characterisation (CROMA) [7][10], IV) Finally he/she will take part in hydrodynamic flow tests (LEGI/CROMA) [2-3]. The aim will be to control the flow around a hydrodynamic profile by deforming it (morphing) using piezoelectric actuators and to close the control circuit using feedback from the sensor developed as part of the thesis.

The PhD student will work in a team with Master’s students, in particular to develop the packaging of the device and then the instrumentation (G2ELAB/ CROMA), in collaboration with PhD students focusing on the development of ZnO nanowires (CROMA/LMGP) and finally in collaboration with PhD students from LEGI to put the sensor into concrete application in the hydrodynamic tunnel (LEGI).

.

References :

[1] Schlichting, H. & Gersten, K., Boundary-Layer Theory, Springer Berlin, (2019), /10.1007/978-3-642-85829-1

[2] Hoerner, S., et al. Experiments in Fluids 62, 104 (2021). 10.1007/s00348-021-03186-8

[3] Abbaszadeh, S., Hoerner, S., et al, IET Renewable Power Generation,13, 16 (2019). 10.1049/iet-rpg.2019.0309

[4] Delafin, P.-L., et al Energies. 14. 667. (2021) 10.3390/en14030667.

[5] Bui Q C, Ardila G, et al., Mater. Adv. 3 498–513, 2022

[6] Manrique M, Consonni V, Ardila G et al., Nano Trends. 9 100066, 2025

[7] Jalabert T, Pusty M, Mouis M and Ardila G., Nanotechnology 34 115402, 2023

[8] A. J. Lopez Garcia, M. Mouis, T. Jalabert, A. Cresti, G. Ardila, Journal of Physics D: Applied Physics 56 125301 2023. DOI 10.1088/1361-6463/acbc86

[9] J. Lopez Garcia, M. Mouis, V. Consonni and G. Ardila. Nanomaterials, vol. 11(4), p.941 2021. https://doi.org/10.3390/nano11040941

[10] Parmar M, Leon Perez E A A, Ardila G, et al 2019 Nano Energy 56 859–67

Location :

The candidate will work in the Micro Nano Electronics Devices (CMNE) team at the Centre de radiofréquences, d’optique et de micro-nanoélectronique des Alpes (CROMA) and in the Énergétique team at the Laboratoire des Écoulements Géophysiques et Industriels (LEGI). The candidate will work in collaboration with the Nanomaterials and advanced heterostructures (NanoMAT) team at the Laboratory in Materials Science and Physical Engineering (LMGP).

Internet links: https://croma.grenoble-inp.fr/en, http://www.lmgp.grenoble-inp.fr/en , http://www.legi.grenoble-inp.fr

Profile and skills required: :

The candidate has to be a student at an engineering school or Master 2 in the fields of electronics, nanosciences and/or the physics of semiconductors or micro/nano systems or related. Knowledge of one or more of these areas is desirable: semiconductor physics, finite element simulation, atomic force microscopy (AFM), clean room techniques and associated characterisations (SEM, etc.). Knowledge of mechanics and fluid mechanics will be an advantage. The grades and rank obtained in the bachelor’s and especially the master’s degrees are very important selection criteria for the doctoral school. Specific skills in teamwork and oral and written communication in English will be appreciated. We are looking for dynamic and highly motivated candidates.

Doctoral thesis funding::

Funding is available via the PEM cluster (2025 – 2028), which brings together CROMA, LMGP, G2ELAB and LEGI in the Grenoble region..

Contacts

Dr. Gustavo ARDILA (CROMA) Tel : 04.56.52.95.32

Dr. Cécile GHOUILA-HOURI (CROMA)

Dr. Stefan HOERNER (LEGI) Tel : 04.76.82.50.35

- Keywords : Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT

- Laboratory : CROMA / FMNT

- CEA code : CROMA-CMNE-05-14-2025

- Contact : gustavo.ardila@univ-grenoble-alpes.fr

- This Thesis position has been filled. Thank you for your interest

(filled) Edge-AI Solutions for Real-Time Hyperfrequency Material Characterization

Start date : 01/09/2025

offer n° CROMA-DHREAMS-03-10-2025

HyperAI: Edge-AI Solutions for Real-Time Hyperfrequency Material Characterization

Context:

The electrical characterization of materials at hyperfrequencies is essential for understanding their intrinsic electronic

structure and charge carrier dynamics. Permittivity and dielectric losses are a major concern in this field, as they directly impact signal

integrity and propagation within high-speed electronic systems. Due to the stringent requirements of advanced System-on-Chip (SoC)

and System-in-Package (SiP) technologies, in situ measurements are necessary, as manufacturing processes (ie solvent deposition,

drying, and polishing) can significantly alter the electrical properties of materials, thereby affecting the overall performance of

interconnects operating at frequencies from 8 to 20 GHz. Conventional methods typically involve two stages: first, measuring the S

parameters of the structures using a Vector Network Analyzer (VNA), followed by solving the inverse problem through back-simulation

(Houzet, 2021). The latter step is computationally intensive, often relying on simulation through finite element methods (such as Ansys

HFSS) to address our specific challenges. Conducting such instrumentation remains a significant scientific challenge, particularly due

to the high computational effort required and the lack of automation in such a method.

Integrating AI-driven instrumentation could streamline the process, reducing computational load and enhancing the efficiency

of inverse problem-solving. A new hardware design is emerging from neural networks implementation with electronic circuits, often

named edge AI. Artificial Neural Networks (ANNs) are computational models designed for real-time computing for applications such

as classification of material samples through their data characteristics. Spiking Neural Networks (SNNs), also referred to as the third

generation of ANNs, are emergent devices who effectively bridge the gap between ANNs and natural intelligence in low-power devices

(Shrestha, 2022). This enables the implementation of AI solutions in-situ, ie as close as possible to the material under test. The

implementation of SNNs is performed on neuromorphic processors such as Truenorth (DeBole, 2019), SpiNNaker (Furber, 2014), and

Loihi (Orchard, 2021). These solutions fully exploit the sparsity of events and offer remarkable efficiency. However, neuromorphic

chips cannot still be considered mainstream in the market, due to costs and availability. A low-cost, low-power solution is found on

hardware-friendly neural networks in micro-controllers such as TinyOL (Ren, 2021), TinyTL (Cai, 2020), and MCUNet (Lin, 2020).

Objective:

The main goal of HyperAI is to accurately characterize the complex permittivity of materials using edge-AI solutions for

real-time computing. This is approached through a two-stage methodology:

- a. Extraction method using transmission lines (e.g., CPW, CPWG, CPS) is employed on materials with known properties to build

a database of measurement data. By varying transmission line types on the same material, we can create a robust dataset suitable

for training a neural network, enabling automated and efficient material characterization. - b. Transform an AI model into a hardware-friendly model. Flexibility, surface area, latency, memory consumption, energyefficiency, and reliability are addressed by this study. An STM32 (B-U585I-IOT02A) and an FPGA (ICE40UP5K-B-EVN)implementation should be investigated.

Keywords:

microwave instrumentation, convolutional neural networks, edge-AI, IoT.

Project Supervision:

CROMA laboratory is represented by Pietro M. FERREIRA, Full Professor at Université de Savoie Mont Blanc,

and Gregory HOUZET, Associate Professor at Université de Savoie Mont Blanc. Prof. FERREIRA has a research interest in microwave

instrumentation, neuromorphic circuits, and ultra-low power solutions. Prof. HOUZET has a research interest in materials science,

microwaves, and applied physics. Candidate will be to the tools and scientific methods of the research topic. Practical activities and

real-world scenarios are planned, including microwave measurements, scientific writing, communication and public speaking, result

quality, time management, and research project management.

Candidate Profile:

The candidate profile required for the project is a young professional holding a master’s degree in Eletrical or

Electronics Engineering, interested in the scientific field of embedded electronics, microwave, and AI. He/She must be motivated,

passionate about research in a multidisciplinary field and an organized person using scientific methods. He/She must justify good

academic tracks in maths and applied physics; an experience in design flow; linguistic competence in English (B2 written and spoken);

linguistic competence in French is a plus.

Intellectual Property:

Being fundamental scientific research, this subject is not attached to any industrial project. Intellectual property

will be promoted through scientific communications favoring the open science policy of the French government.

Bibliography:

10.1016/j.mejo.2021.104990, 10.1109/MCAS.2022.3166331, 10.1109/MC.2019.2903009, 10.1109/JPROC.2014.2304638,

10.1109/SiPS52927.2021.00053, 10.1109/IJCNN52387.2021.9533927, https://dl.acm.org/doi/abs/10.5555/3495724.3496671,

https://dl.acm.org/doi/abs/10.5555/3495724.3496706.

- Keywords : Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT

- Laboratory : CROMA / FMNT

- CEA code : CROMA-DHREAMS-03-10-2025

- Contact : marisfep@univ-smb.fr

- This Thesis position has been filled. Thank you for your interest

(filled) Alternative methods based on dynamic detection for a new generation of ISFET-like biosensors in graphene

Start date : 01/10/2024

offer n° CROMA-CMNE-05-31-2024

Alternative methods based on dynamic detection for a new generation of ISFET-like biosensors in graphene

Deadline for application: 18th of June 2024, beginning of contract: 1st of Oct. 2024

Place:

CROMA (Minatec) and Néel Institut, Grenoble (France)

Advisors:

Irina Ionica (Associate Professor Grenoble INP),

Cécile Delacourt (CNRS rechercher, Néel Institut),

Context and objectives:

This thesis is placed in the context of biochemical detection with ISFETs (Ion Sensing Field Effect Transistors), for which

the current which passes through the transistor channel is modulated by the presence of the charges to be detected

in its proximity. In the majority of cases, detection is done in real time by monitoring the drain-source current of the transistor channel.

in its proximity. In the majority of cases, detection is done in real time by monitoring the drain-source current of the transistor channel.

Quantitative measurement could be done by calibrating the drain current as a function of the gate voltage of the transistor relative to the load to be detected. This method which has already been used for many demonstrators and

applications, uses the monitoring of a quantity quasi-static (e.g. the threshold voltage of the transistor), which non-discriminatorily encompasses all type of charge contained in the solution and sufficiently close to the channel (ions, fixed charges adsorbed on the surface of the device, interface states etc).

Unfortunately, in a “non-laboratory” application, a solution does not only contain the element we wish to detect, but many others and it would be important to identify typical electrical responses associated with the constituents. Dynamic approaches, such as non-equilibrium potential or low-frequency noise, are promising because they offer, for example, the possibility of searching for specific signatures depending on the measurement frequencies.

The objective of this project is therefore not to show another demonstrator which would improve one or several

figures of merit for a given application, but rather to explore dynamic detection alternatives with an ISFET, to

study/identify the mechanisms that are responsible for the particular electrical responses of the sensor. At

CROMA, we showed that the out of equilibrium body-potential response in device fabricated on silicon-on

insulator (SOI) 1 and due to the presence of Schottky barriers at the contacts2 can be used for sensing3.

The aim of this thesis is first to implement similar methods for graphene field effect transistors and benchmark

the dynamic detection with the quasi-static and more conventional approach. At Neel, we have demonstrated

the ability to fabricate array of GFETs that offers many suitable properties for sensing living matters4 and

biochemical compounds5. Sensors manufactured on graphene will benefit from the flexibility of the technology

in order to study a wide range of options to understand the mechanisms involved and to optimize the sensors.

Modelling and simulation components will elegantly complete the project for understanding of the phenomena

and will provide keys for the optimization of future sensors.

Work do be done:

The PhD student will develop the complete chain, from device fabrication, electrical measurements in equilibrium and dynamic conditions, sensing layer and surface functionalization for specific detection applications, modeling and simulation, allowing the comprehension of physical phenomena involved

and the optimization for the sensor. To remain more generic at first, ionic solutions close to those used in cell culture media with compositions simplified (e.g.: a single type of ion) and variable concentrations will make it possible to evaluate the mechanisms and detection improvements with dynamic methods (nonequilibrium potential and/or low frequency noise). More pragmatic applications will be explored in the second half of the thesis (e.g. neuronal sensing).

1M. Alepidis, A. Bouchard, C. Delacour, M. Bawedin and I. Ionica, “Out-of-Equilibrium Body Potential Measurement on Silicon-on-Insulator

With Deposited Metal Contacts,” in IEEE Transactions on Electron Devices, vol. 67, no. 11, pp. 4582-4586, 2020

2M. Alepidis, G. Ghibaudo, M. Bawedin & I. Ionica, Origin of the Out-of-Equilibrium Body Potential In Silicon on Insulator Devices With

Metal Contacts. IEEE Electron Device Letters, 42(12), 1834-1837, 2021

3M. Alepidis, A. Bouchard, C. Delacour, M. Bawedin, & I. Ionica, Novel pH sensor based on out-of-equilibrium body potential monitored in

silicon on insulator with metal contacts. In ECS Meeting Abstracts (No. 59, p. 1589). IOP Publishing, 2021

4Dupuit, V., Terral, O., Bres, G., Claudel, A., Fernandez, B., Briançon-Marjollet, A., & Delacour, C. (2022). A multifunctional hybrid graphene

and microfluidic platform to interface topological neuron networks. Advanced Functional Materials, 32(49), 2207001.

5Terral, O., Audic, G., Claudel, A., Magnat, J., Dupont, A., Moreau, C. J., & Delacour, C. (2024). Graphene field-effect transistors for sensing

ion-channel coupled receptors: towards biohybrid nanoelectronics for chemical detection. arXiv preprint arXiv:2402.04378.

Knowledge and skills required:

The candidate must have a solid knowledge of physics of semiconductors and devices. Clean-room fabrication, electronics of measurement systems, notion of chemical physics, surface physics or electrochemistry would be appreciated to better understand the interaction at the interface with the top gate liquids. The candidate is expected to enjoy experimental work and the development of adapted measurement protocols.

Scientific curiosity, motivation, creativity, tenacity are mandatory qualities in order to take full advantage of the scientific environment of this thesis and to gain excellent expertise for his/her future career. The topic is in the field of applied physics, but close to the fundamental physics, as well as to the industrial world. After the PhD, the candidate will easily adapt to both academic and industrial research environments.

The candidate must have a very good academic record, with high grades.

For the application, send your CV, motivation letter, track of records for your masters and recommendation letter(s).

- Keywords : Engineering science, Engineering science, Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT

- Laboratory : CROMA / FMNT

- CEA code : CROMA-CMNE-05-31-2024

- Contact : irina.ionica@grenoble-inp.fr

- This Thesis position has been filled. Thank you for your interest

(filled) Simulation, fabrication and characterization of transparent piezoelectric transducers based on ZnO nanowires

Start date : 01/10/2024

offer n° CROMA-CMNE-05-28-2024

Simulation, fabrication and characterization of transparent piezoelectric transducers based on ZnO nanowires

Detailed Topic

Piezoelectric devices are attracting growing interest as a micro-source of energy by harvesting mechanical ambient energy, and as sensors via the direct piezoelectric effect. In this context, semiconducting materials in the form of nanowires constitute a promising building block for the fabrication of innovative devices. The nanowires typically exhibit diameters of several tens of nanometers along with a length of around one micrometer. Thanks to that geometry, they generally present an excellent crystalline quality and benefit from remarkable physical properties that are related to their high surface/volume ratio. Zinc oxide (ZnO) as a biocompatible semiconductor composed of abundant elements specifically has numerous assets and can be grown in the form of nanowires by a large number of deposition techniques. Owing to its wurtzite crystalline structure, ZnO nanowires grow along the piezoelectric c-axis. Vertically aligned ZnO nanowire arrays are thus sensitive to mechanical constraints and are liable to be integrated into piezoelectric nanocomposites aiming either to sense mechanical inputs (e.g. fingerprint scanners) or at harvesting with a good efficiency the mechanical energy in the environment and hence playing the role of an energy micro-source.

The objective of this PhD thesis is to explore theoretically and experimentally the performance improvement of high-density arrays of ultimate-size ZnO NWs on a transparent substrate (i.e. glass) covered by a transparent conductive electrode (AZO, etc.). ZnO nanowires with controlled dimensions and properties (surface states, doping) will be developed using a low-cost, low-temperature, chemical deposition technique with a low environmental impact and a high industrial potential. The integration into devices will be performed based in the know-how of the laboratory consortium. Advanced complementary characterization techniques will be used at device and nanowire level: Home-made set-ups will be used at device level. Complementary AFM platforms (SSRM, SCM, TUNA, SMIM, etc.) will be used to characterize single nanowires. All these experimental data (geometry, doping, surface states) will help us to build and validate a simulation platform both at single nanowire and device level. The simulation platform will provide optimization guidelines for future devices sensors and energy harvesting devices.

References:

1. M. Parmar et al. Nano Energy 56 859-867 (2019). DOI: ttps://doi.org/10.1016/j.nanoen.2018.11.088

2. S. Lee et al. Adv. Funct. Mater. 24 1163-1168 (2014). DOI: https://doi-org.gaelnomade-2.grenet.fr/10.1002/adfm.201301971

3. J. Villafuerte et al, Nano Energy 114 108599 (2023), https://www.sciencedirect.com/science/article/abs/pii/S2211285523004366

4. T. Jalabert et al. Nanotechnology 34 115402 (2023). DOI 10.1088/1361-6528/acac35

5. R. Tao et al., Adv. Electron. Mater. 4(1) 1700299 (2018). DOI: 10.1002/aelm.20170029

6. A. Lopez et al, Nanomaterials 11(4) 941 (2021). https://doi.org/10.3390/nano11040941

7. A. Lopez et al., Journal of Physics D: Applied Physics 56 125301 (2023). DOI 10.1088/1361-6463/acbc86

8. C. Lausecker et al. Inorganic Chemistry 60 (3) 1612-1623 (2021) https://doi-org.sid2nomade-2.grenet.fr/10.1021/acs.inorgchem.0c03086

9. Q. C. Bui et al., ACS Appl. Mater. Interfaces 12 (26) 29583–29593 (2020) https://doi-org.sid2nomade-1.grenet.fr/10.1021/acsami.0c04112

10. M. Manrique et al., Energy Technol. 2301381 (2024), https://onlinelibrary.wiley.com/doi/10.1002/ente.202301381

Location

The candidate will work in the Micro Nano Electronics Devices (CMNE) group from the Centre for Radiofrequencies, Optic and Micro-nanoelectronics in the Alps (CROMA), in the Nanomaterials and advanced heterostructures (NanoMAT) group from the Laboratory in Materials Science and Physical Engineering (LMGP), in the PROSPECT group from LTM and the Nanocharacterization platform team (PFNC) from CEA-LETI.

Web sites: https://croma.grenoble-inp.fr/,

http://www.lmgp.grenoble-inp.fr/,

https://ltm.univ-grenoble-alpes.fr/,

https://ltm.univ-grenoble-alpes.fr/research ,

https://www.leti-cea.fr/cea-tech/leti/Pages/recherche-appliquee/infrastructures-de-recherche/plateforme-nanocaracterisation.aspx

Profile & Required Skills

The applicant should be an Engineering School or Master 2 student in the fields of electronics, nanosciences and/or semiconductor physics. It is desirable that the candidate has knowledge in one or more of these areas: semiconductor physics, finite element simulation, Atomic Force Microscopy (AFM), clean room techniques and associated characterizations (SEM, etc.). The grades and the rank as undergraduate and especially at the Master degree are a very important selection criterion for the doctoral school. Specific skills for teamwork and oral and written English expression will be appreciated. We are looking for dynamic and highly motivated candidates.

PhD Thesis Funding:

Funding is available via the Microelectronics LABEX (2024 – 2027) joining CROMA, LMGP, LTM and CEA-LETI in the Grenoble region.

Contacts

Dr. Gustavo ARDILA gustavo.ardila@univ-grenoble-alpes.fr Tel : 04.56.52.95.32

Dr. Vincent CONSONNI vincent.consonni@grenoble-inp.fr Tel : 04.56.52.93.58

Dr. Bassem SALEM bassem.salem@cea.fr Tel : 04.38.78.24.55

Dr. Gwenael LE RHUN gwenael.le-rhun@cea.fr Tel : 04.38.78.12.29

- Keywords : Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT, Leti, LMGP, LTM

- Laboratory : CROMA / FMNT / Leti / LMGP / LTM

- CEA code : CROMA-CMNE-05-28-2024

- Contact : gustavo.ardila@univ-grenoble-alpes.fr

- This Thesis position has been filled. Thank you for your interest

Co-Integration of Photonic Multichip Module for THz Frequency Generation

Start date : 01/10/2024

offer n° CROMA-PHOTO-03-19-2024

Co-Integration of Photonic Multichip Module for THz Frequency Generation

KEYWORDS :

Laser, Integrated Optics, TeraHertz, Communications

CONTEXT:

The technological development of communications devices, new and futures uses such as video conferencing, streaming, Internet of Things (IOT), 6G, AI, continue to further increase the pressure on telecommunications systems to reduce latency while simultaneously increasing both data rates and the number of connected devices. This recurring problem in the world of telecommunication leads to different communication generation (3G,4G, 5G…).

The frequency bands currently used for telecommunications already cover a large part of the spectrum, including the experimental bands at 60 GHz in the 5G standard. To tackle this problem, 6G plans to use sub-terahertz frequencies (>100GHz) and European roadmap expects to launch commercial products as soon as 2030. Systems operating at such frequencies are difficult to conceive because they are not compatible with standard architectures. Optical technics offer competitive solutions to reach these band, and even higher frequencies. Such realization is also of interest for a wide range of application, including spectroscopy, sensing, radars…

The ideal solution would rely on high performance integrated devices, compatible with current communications systems and capable of evolving to meet the demand of future needs.

At the CROMA laboratory, we recently demonstrated the use of co-integrated lasers on glass for communication system and the generation of continuous carrier at frequency up to terahertz (300GHz) with outstanding spectral properties.

OBJECTIVES:

The PhD work will be carried out as a part of a national research project, involving academic and industrial partners. Our goal is to fabricate a co-integrated multi-chip module for the generation and high speed modulation of terahertz signals. The candidate will focus on the design, manufacturing, characterization and simulation of the laser modules. The integrated laser chips will be produced using the technological facilities available at the CROMA,

including dedicated clean room, with the help of technical support, and advanced characterization systems (atomic force microscopy, dedicated optical benches…).

The laser chip will be optically and mechanically interfaced with a Lithium Niobate chip realized by an industrial partner, specifically for this project. Consequently, the applicant will be involved in the co-design of the two structures and in the definition of interconnecting solution of the two chips. The module will be packaged to be characterized and tested by different partners. The candidate will be involved in experiments at the different sites during

the project.

EXPECTED WORK:

- Model and simulation of the manufacturing process, including the fabrication of waveguides using ion exchange techniques and the realization of Bragg grating by photolithographic process.

- Laser Manufacturing including clean room process, molecular bonding, dicing and polishing

PhD Position

- Characterization of components, including geometrical (AFM) and optical evaluation (mode profile, gain/loss, spectral measurements… )

- Advanced characterizations: optical intensity noise, optical and RF linewidth will be estimated using opto-RF characterizations. Preliminary communication experiments will be carried-out at the CROMA laboratory using advanced modulations, including optical coherent formats.

- Collaboration with industrial and academic partners from design to experimental validation.

The work plan is composed of different steps:

- bibliographic studies to determine the current state-of-art and position the thesis results

- Analysis and handling of in-house existing simulation tools

- trainings on fabrication process and characterization tools

- reporting : technical reports, scientific publication and conferences

APPLICANTS:

We are looking for candidates inclined to develop advanced skills in the manufacturing and characterization of integrated optics and laser devices. Theoretical training in electromagnetism and laser physic is highly recommended, if not essential. The doctorate will benefit from an environment recognized both for its scientific level (in the top 5 of the world’s innovative cities, 25.000 researchers, 65000 Students…) and for its environment (French Alps).

The laboratory facilities being located in secured areas, the final decision is also depending on the acceptance of the application by a security officer.

The thesis funding is part of a national research project already underway.

Applications should include CV, cover letter, academic marks and diplomas.

Expected starting date: Oct. 2024

For more details, please contact:

Julien POËTTE julien.poette@grenoble-inp.fr

Lionel BASTARD lionel.bastard@grenoble-inp.fr

Jean-Emmanuel BROQUIN jean-emmanuel.broquin@grenoble-inp.fr

- Keywords : Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT

- Laboratory : CROMA / FMNT

- CEA code : CROMA-PHOTO-03-19-2024

- Contact : julien.poette@grenoble-inp.fr

Contact us

Contact us How to find us

How to find us

Telecharger ma sélection

Telecharger ma sélection Reset

Reset